Industry News | Date:2022-04-19 | View:1030

How to choose non-standard visual inspection equipment that meets your product inspection needs?

How to choose non-standard visual inspection equipment that meets your product inspection needs? The editor summarizes the following main aspects to consider:

1. After sales. After the equipment fails, make sure that there is a professional maintenance team to deal with the equipment within a certain period of time.

2. Integration. Fasteners, machined parts are available in thousands of models and sizes. The choice of machine vision inspection equipment, whether it can detect a variety of products, is also a major consideration in the manufacturing industry. Some devices on the market can only be used for one product, or even only one size. So for a company with multiple products, it's a huge cost burden.

3. The accuracy of screening. Most people think that if the detection accuracy is to be improved, the configuration of the camera must be improved, but in fact the accuracy of visual inspection is affected by light and lens. Most manufacturers will recommend that you purchase a high-precision camera to improve the accuracy of your tests, but in many cases, the right light source and lens can meet the customer's needs. Don't forget that high precision cameras increase the processing time of the computer and affect the detection speed.

4. Test items. The machines on the market have no problem with basic dimensions. At present, few manufacturers can actually detect defects (such as rupture, crush, deformation, etc.), but in the production process of fasteners, there will inevitably be defects, if manual inspection is used, it will consume a lot of manpower and time, and it is easy to miss the inspection and cause customer complaints. In fact, if the light is properly designed and designed according to the characteristics of the product, so that the product's reflection of the light is correctly projected on the lens, the above-mentioned defects such as crushing can be easily solved.

5. Screening speed. Speed determines productivity. If a machine is to replace a large number of human inspections, speed must be considered first. In the market, machine sellers have different opinions. Basically, in addition to the feeding speed, the detection content and the speed of the camera also have a certain impact.

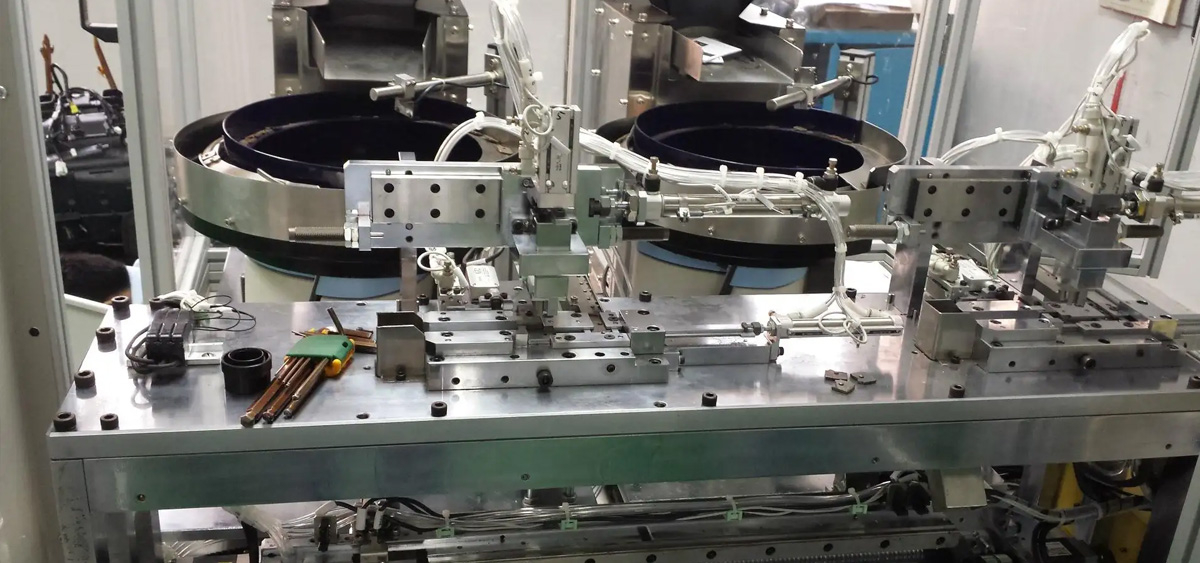

6. Wholeness. In addition to the optical requirements of the screening machine, the structure of the mechanism design is also very important. Whether the feeding is smooth or not, and whether the delivery of good products and the rejection of defective products after the inspection is completed also account for a large consideration when purchasing equipment.

Related news

- Several major industry forecasts for the application of dispensing equipment in 2022

- A survey on the application market distribution of domestic automatic glue dispensers

- What are the main categories of automation equipment?

- What are the characteristics of non-standard automation equipment?

- How to choose non-standard visual inspection equipment that meets your product inspection needs?

![Non-standard automation_dispensing machine_sheet metal processing_optical fiber end face cleaning and inspection_Xiangtong Intelligent [official website] Non-standard automation_dispensing machine_sheet metal processing_optical fiber end face cleaning and inspection_Xiangtong Intelligent [official website]](/uploads/image/20220622/289c61a1990d3e1b10e46234a4ea45a8.png)